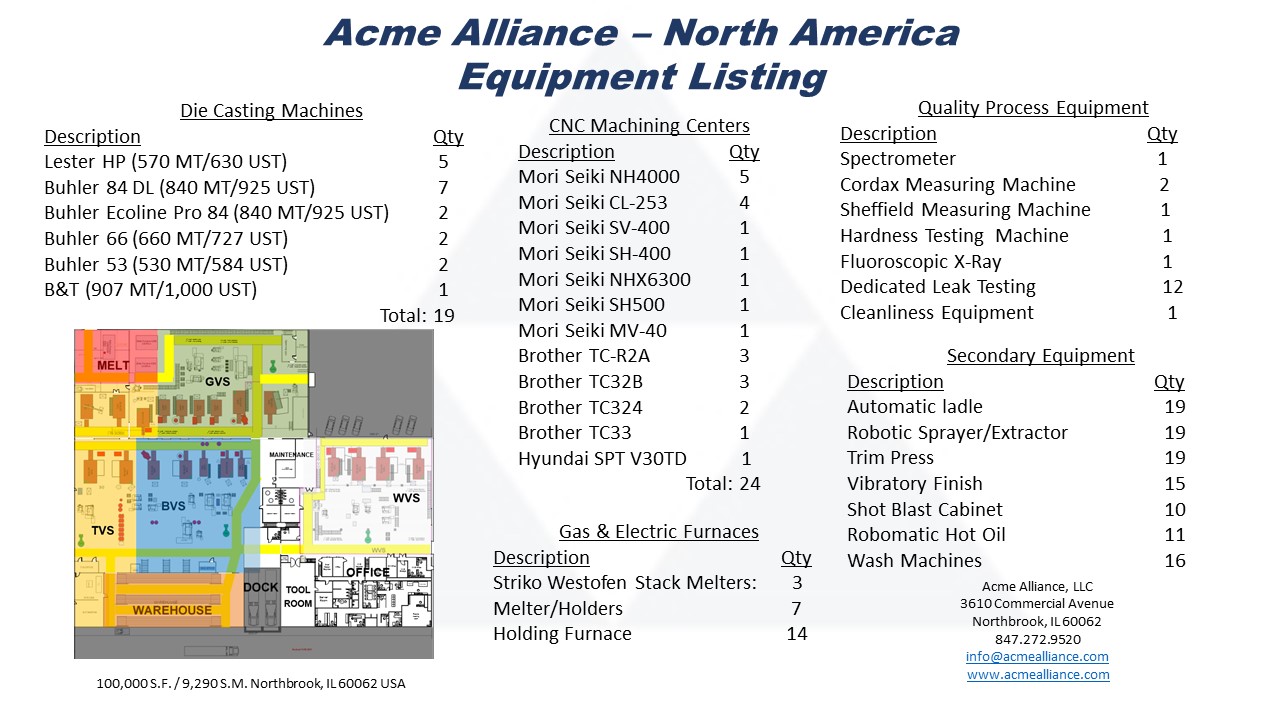

Quality Standard

Acme Alliance's value stream production system is established to control process flow, reduce waste and improve quality. State of the Art Buhler Die Cast equipment provides the latest technologies and statistical-process control (SPC) methods.

Production Standard

Castings are produced on automated 530, 660, and 840 metric ton Buhler Die Casting equipment. Acme’s complete tonnage range is between 500 and 1,200 US. Production equipment is standardized worldwide. Ladle, shot, part extraction, and die spray are automated.

Secondary Finishing

Vibratory finishing, shot-blasting, roto deburring, and washing are performed immediately after cast and trim on right sized equipment assuring one-piece flow handled by a single operator.

CNC Machining

Post machining operations are produced in house within a given floor space. Large CNC machining and lathe work is produced on Mori Seiki machining centers. Smaller CNC work is produced on Brother machining centers. Dedicated machining equipment, including multi-spindle drill and tapping, are utilized where they add value.